The Laser Pipe Tally System by Digi-Tally, Inc. provides a complete battery operated mobile field pipe tally system for use at the job site, in pipe yards, or in manufacturing facilities. The length of each pipe joint is measured using an advanced class II eye safe laser and the data is processed on a mobile field controller.

The Laser Pipe Tally System by Digi-Tally, Inc. provides a complete battery operated mobile field pipe tally system for use at the job site, in pipe yards, or in manufacturing facilities. The length of each pipe joint is measured using an advanced class II eye safe laser and the data is processed on a mobile field controller.

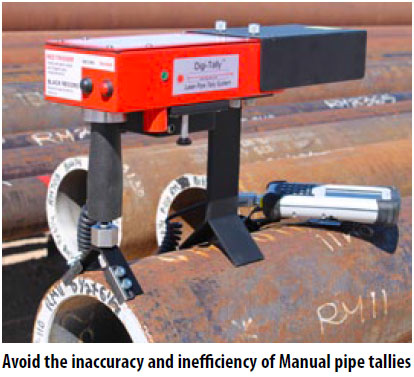

The Digi-Tally unit rests on the pipe with a rugged alignment support and is equipped either with our unique top thread locator (patented) for “threadsoff” joint tallies or our pipe end locator for “threads on” tallies. The visible red laser spot is bright and visible on the target at the far end of the pipe.

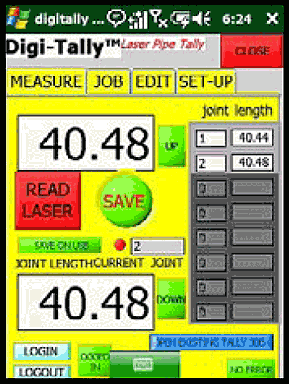

Tally measurements are recorded and stored on a rugged mobile field controller which offers several methods of transferring data after a job has been completed.

Perform the tally, then automatically create a complete text based report that can be printed, viewed, and saved electronically for future reference. The tabulated tally data can also be sent to inventory management systems and drilling programs for paperless record keeping.

In the event that an operator error is made, users can manually edit a measurement or acquire a new

measurement via the laser system.

In the event that an operator error is made, users can manually edit a measurement or acquire a new

measurement via the laser system.

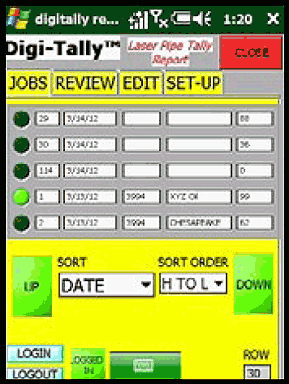

Select the job you need to create a report for by simply clicking the radio button to the left. It is also possible to edit a job’s tally data in case an error was made during the tally.

The Digi-Tally Report application incorporates an auto-check routine and alerts the user of any anomalies

in joint length. The bar plot of joints also provides a visual indication of length irregularities prior to generating the report.